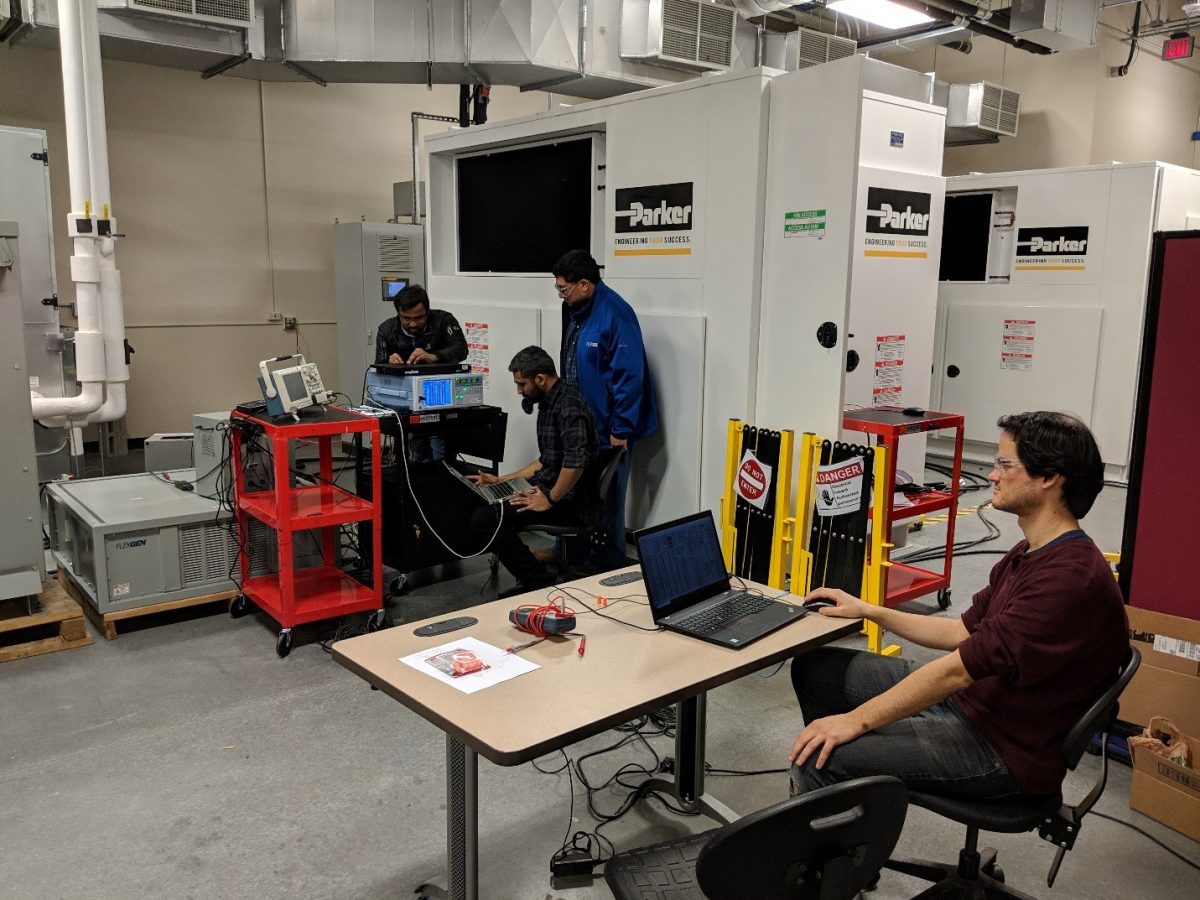

Lab Capabilities, Related Labs, and Equipment

The Flexible Energy Laboratories Suite contains the following equipment and modules:

- ASD Power cables and conductors load cycle testbed rated 4000 A

- Haefely-Hipotronics high voltage insulation test system rated 100 kV (upgradable to 300 kV)

- 1 MVA rated Grid Simulator including 4160V medium voltage testbed

The Flexible Energy Laboratories Suite at EPIC offers a secure environment to conduct standard compliance as well as functional performance testing of power and energy systems. This laboratory provides a test and pre-certification environment for high-power electronic equipment.

- Testing “Power Converter Cores” in applications such as motor drives, photovoltaic power conversion, wind power conversion, battery energy storage, high voltage DC conversion, electric vehicles, and railway traction.

- Standards testing of Power Electronic Systems.

- Testing medium voltage ac components such as switchgear and circuit breakers up to 4160V.

- Evaluating passive components such as capacitors, reactors, and heat sinks employed in power electronic applications.

- High voltage testing area rated up to 100kV for testing cables, overhead wires, transformers and other high voltage equipment.

- The load cycle testbed is capable of injecting up to 4000 A using current transformers, to analyze the thermal performance of the cable / overhead wire. The system is also used to develop control algorithms for maximizing the utilization of the cables and lines.